At Nature's Lab, we take pride in providing high-quality supplements you can depend on. We work hard to keep the trust and loyalty of our customers by dedicating ourselves to high quality supplements at every stage- from initial research all the way to your doorstep.

High Quality Ingredients

We utilize high quality, natural, and safe ingredients. Our formulas are free from harmful fillers, artificial colors and flavorings, and synthetics containing alcohols, strong detergents, and dangerous chemicals.

Customized Variety of Products

We provide natural vitamins thoughtfully formulated to meet a wide variety of nutritional needs for men and women.

Our Research & Development team is committed to bringing you the most effective supplements based on leading, reliable scientific research.

Exceptional Lab Testing

Our in-house-lab conducts testing on purity, potency, stability, identity and more to ensure safe, clean and efficacious products with the most advanced microbiological analysis.

State-of-the-Art Facility

Our 55,000 sq ft. facility is triple HEPA filtered, climate controlled and equipped with over 90 quality control checkpoints and premium machinery so we can provide the top-quality supplements on the market.

We utilize branded ingredients, proprietary blends, and other top-sourced raw materials from our trusted supply partners.

Clean Labels

We are committed to clean labeling practices using only safe and necessary ingredients.

Sustainability Practices

We are committed to sustainable sourcing, manufacturing, labeling and packaging, utilizing How2Recycle compliant packaging when available.

Customer Satisfaction Guarantee

We are committed to making products you’ll love. We offer a 90-day money-back guarantee. If you aren’t satisfied with your purchase from us, we’ll make it right.

USP Audited Facility

Our facility is regularly audited by the independent third party USP, ensuring our supplements meet high standards of production quality.

Founded in 2011 in Las Vegas, Nature's Lab has been producing high quality dietary supplements based on the latest science for nearly a decade. We take great pride in manufacturing without any quality compromises. Each formula is meticulously developed to provide the right nutrients, in the right forms, and at the optimal potency levels to produce the best supplements on the market. Four core Nature's Lab pillars drive this work:

SCIENTIFIC FORMULAS

Formulated in-house by our team of experts, Nature's Lab dietary supplements are based on the most recent leading nutritional science.

QUALITY

Nature's Lab is dedicated to delivering quality products. From raw ingredients to finished products, each formula must pass extensive quality checkpoints without any compromises.

Facilities: All of our products are produced in our in-house manufacturing facility and lab located in Las Vegas, Nevada. This 55,000 square foot complex includes state-of the-art equipment, a newly designed quality system, universal climate control, and HEPA filtration year-round for product stability and purity. The facility is also certified by the United States Pharmacopeia (USP) to achieve Current Good Manufacturing Practice (cGMP) to ensure the highest possible standards are met.

Our experienced experts base each of our supplement formulas on the latest leading science-based studies in order to provide consumers with the results they've come to trust from our products. Dedicated to excellence, Nature's Lab sources only the highest quality raw materials available on the market to go into these formulas. Our direct and transparent sourcing approach means that we verify, build a trusting relationship with, and even visit our raw material suppliers to ensure only the best gets to your door.

Quality Testing: Nature's Lab has over 90 quality control checks in place throughout the manufacturing process. This starts with the raw materials. Immediately upon reaching our facility, all raw materials are quarantined and inspected before verifying their certificates of authenticity. To guarantee authenticity, Nature's Lab quality requirements demand that each product be free from contaminants as well as consistent in identity, purity, strength and composition. Every raw material entering a formula is tested for odors, heavy metals, bacteria, known contaminants, and concentration. Once blended using one of our premium German machines, the finished products are encapsulated, re-tested for identity and purity. Every step of our production process guarantees that our customers receive only the best final product. We believe in our products so much that we stand behind them with a 90-day money back guarantee.

Nature's Lab has hand selected state-of-the-art vitamin machinery, for exceptional quality, cleanliness, and efficiency.

The Agilent 7900 ICP-MS

The Agilent 7900 is known as the next generation heavy metal detection unit that features a matrix that enables our team of specialists to measure samples containing up to 25% total dissolved solids. This measurement is far beyond the capability of any other system currently available. The Agilent 7900 also features better trace level detection to guarantee that our products contain exactly what’s on the label.

High-Performance Thin-Layer Chromatography (HPTLC)

Nature's Lab utilizes the most advanced form of thin-layer chromatography. From precise sample application, standardized reproducible chromatogram development, and software-controlled evaluation, this powerful analytical tool confirms and establishes the identity of every complex mixture and natural product that Nature's Lab manufactures.

Agilent 1260 Infinity II LC

One of the latest High Performance Liquid Chromatography (HPLC) available, HPLC is used to determine the purity of compounds and to specify the exact amount of phytochemicals present in plant extracts and all active ingredients in our products to assure our product meets Nature’s Lab standards.

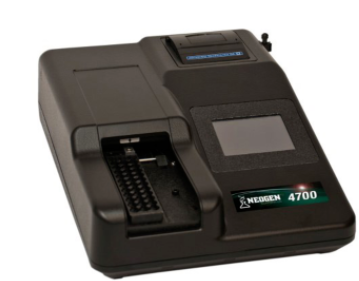

NEOGEN Soleris Next Generation Microbial Testing

The NEOGEN Soleris™ Next Generation Microbial testing is for the purpose of automated microbial testing. Using technology from their BioLumix system, these machines are capable of testing for coliforms, Enterobacteriaceae, yeast, molds, lactic acid bacteria, E. coli, and other bacterias in 48 hours instead of 5-7 days.

The Bosch GKF Capsylon

Our in-house lab features a range of modern German engineered Bosch machines. Among them are four of the fastest and best quality encapsulators ever made in North America. This allows both swift and reliable high-quality production at a 45,000 capsule per hour capacity with flexible support for all capsule sizes and auto rejection of imperfect capsules for superior quality.

The Image 3000 Powder Line

Every package that comes out of our lab must contain the right quantity of the finished product. Filling machines such as auger fillers are used to help package products quickly and accurately. The Image 3000 is ideal for running bottles or containers, with typical filling ranges from 1 gram to 10 pounds for optimal efficiency.

Patented Superior German Blending Technology

The slow-rotating, homogenous mixing achieved from our Bohle blending system creates uniform, gentle blending without destruction of granulates. A lifting column enables adjustable height, ensuring fast and dust-free filling, blending, and discharge. All materials are contained throughout this process, further ensuring that Nature's Lab maintains the quality that customers have come to expect over the years.

Nature's Lab only sells products that we trust and use. With our dedication to wellness in mind, Nature's Lab makes a promise to provide quality dietary supplements for years to come. In the face of socio-economic changes such as fast-paced lifestyles, soil depletion, non-organic food sourcing and more, we understand that some may find it hard to maintain a healthy lifestyle through diet alone. Our supplements are created to help make health and wellness goals attainable for our consumers for generations to come.

Call, email, or text us today with any questions - we love our customers and want your comments, feedback, and suggestions.

Call: (800) 211-4188

Email: service@natureslab.com

Mon - Fri 9am - 5pm Pacific Time